|

A fuel system is just that - a system! All the pieces must work together. The current trend is to run a pump that is much bigger than should be required to compensate for deficiencies within the system. Simply buying and installing the biggest pump you can find will not be enough if the rest of the system is poorly thought out. The same can be true buying a pump based upon price or what you think is enough fuel pump. Either deficiency can also easily drain the wallet if you run out of fuel and start damaging engine parts ... not to mention losing races! This article will focus on electric fuel pumps. Mechanical fuel pumps are not worth the effort unless you are mandated by the rules of your class (as in most circle track applications). You can use the same basic knowledge with your mechanical fuel pump in regards to requirements and fuel regulator choices. Fuel pumps are generally rated in gallons per hour (or GPH). Mallory offers pumps rated at 70, 110, 140, 250 and 500 GPH. All of the Mallory pumps are of gerotor type which makes them quieter and more efficient than rotary vane style pumps. However, it is mandatory that a fuel filter be installed between the fuel cell (or tank) and the pump. The higher efficiency of the gerotor pump also is less tolerant of garbage getting into it ... always run a filter before the pump! You should also have a filter just before your carburetor or injector rail as well. A typical engine uses 0.5 pounds of fuel (gasoline) per hour to make each horsepower. Gasoline weighs in at approximately 6 pounds per gallon. To calculate fuel consumption let me show you by example. Lets say we have a 400 HP engine (or nitrous system) and we will use the following formula:

If you installed a pump rated at 33 GPH on a 400 HP Nitrous system the engine would experience severe fuel starvation and your wallet would cringe in "empty" pain! WHY?

All of this makes choosing a pump size difficult. You may use the following as a fuel pump "rule of thumb".

These minimum pump sizes assume that the fuel system is equipped with fuel lines of adequate size. If the fuel lines are too small (or if there are a lot of restrictive fittings in the system) a larger pump may be required to satisfy the fuel demand of the engine. The minimum fuel line size (from the pump to the regulator) is dependent on the horsepower output of the engine (and/or Nitrous system) regardless of the size of the pump. Use these figures as a fuel line sizing standard:

If you use a return-style regulator, you will also need a return line from the regulator back to the tank. The size of the return line is dependent on the size of the pump you are using, regardless of the engine's horsepower output. The return line must have limited or NO pressure in it. In most cases, the minimum return line size will match that of the supply line, but a larger return line is sometimes preferred. Use these ratings to decide your return line sizing based upon fuel pump output:

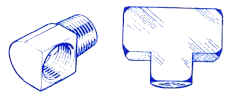

Mounting the fuel pump takes thought as well. You MUST mount the fuel pump as low as possible and as close to the fuel cell (or tank) as possible as well. DO NOT mount the pump above the fuel tank. NOTE: At many times I'm asked about the actual angle of mounting the pump. I'm asked if the pump must be mounted upright. Take it this way, if the seals in the pump happen to fail, would you want fuel leaking into an electric motor or simply onto the ground? Well if you like fires ... Mount the fuel pressure regulator as close to the engine as possible. DO NOT use restrictive fittings, especially sharp 90º or "T" fittings. If you must use a 90º or "T" fitting, use the tube style fittings from Earl's, Russell, Goodridge, Bonaco and others. See Below...

Regulators and the Benefits of Return-Style Systems: One of the biggest restrictions in most fuel systems is the "dead-head' regulator. Dead-head regulators are popular because you do not need to install a return line. However, they are not only more restrictive but also create several other problems that can be eliminated with a return-style regulator. Dead-head regulators also have a higher failure rate than return-style regulators.

Because a dead-head regulator starts and stops flow, fuel pressure between the pump at regulator is higher than the pressure between the regulator and the carb (or injectors). However, if the pressure gets too high, it can and will damage the fuel pump. Therefore, the pressure coming out of the pump is limited by a device built into the pump called a bypass. Low pressure pumps are limited to less than 9PSI and should not be used with dead-head regulators. High pressure pumps are limited to a pressure of between 10 and 25PSI. Not only can the fuel pumps being used with dead head regulators fail because of pressure issues, but pumps with dead head regulators also run hotter do not last as long as when connected to to a return-style system because it is the fuel that cools the pump. Pounding the fuel because it can not move creates more heat. The Mallory 70 and 110 pumps are low pressure pumps that can be used without a regulator for the street or with a return-style regulator for racing. Mallory 140, 250 and 500 series pumps are high pressure/high volume and must be used with a regulator (dead-head or return-style). The bypass in the pump can malfunction. This can cause the pressure to drop or increase so much that the pump motor fails. Even if the bypass in the pump is working correctly, it is still possible to have a pressure drop with a dead-head regulator, even when using a large pump. See the image below:

At idle, gauge #1 will read 10PSI where gauge #2 will read 8 PSI. At full throttle, the increase in fuel flow will create a pressure drop between the pump and the regulator. The amount of pressure drop depends on the restriction in the fuel line ... a 4 PSI drop is not uncommon. Gauge #1 will now read 6PSI and because a dead-head regulator cannot raise the pressure, gauge #2 will also now read at 6PSI. The result is a 2 PSI pressure drop at the carb or Nitrous even though a very large pump may be in use.

Most race pumps have the bypass set very high (14-25 PSI) to avoid this problem. However, this creates another problem. The higher bypass pressure makes the pump work harder and draw more amperage. In fact, the pump works just as hard at idle as it does at full throttle down the track! This is one of the main causes of early pump failure. To counteract this problem of high amperage draw, many companies manufacture voltage reducers for street cars to slow the pump down and increase the life of the pump. A few "WHYS" to return-style regulators: This is a profound point to be made when I (or your engine builder, carb builder or fuel pump manufacturer) tell you to run ONLY a return-style system on your vehicles.

See Below: If there is s 2 PSI pressure drop between the pump and the regulator, the return-style regulator will force the pump to produce 10 PSI. If there is s 4 PSI drop, the pump will be forced to produce 12 PSI. In either case, the pressure at the regulator will remain at 8 PSI (or whatever you set it at). The pump will also live longer since it is only producing 10-12 PSI instead of 14-25 PSI. This means that a voltage reducer is not needed, even on a street car. Fuel pressure regulators suffer from something called "recovery time". Recovery time is explained as the amount of time it takes the regulator to react to changes such as a sudden increase in fuel demand (as when you jump on the throttle or hit the Nitrous button). Return regulators react much quicker for several reasons. Return regulators allow the fuel to flow straight through without making a 90° turn. With a return regulator the fuel doesn't have to make it's way around the plunger like it does in a dead-head regulator. Just before you jump on the throttle (or hit the nitrous button), the fuel in a dead head system is barely moving. In a return system, the fuel is constantly moving from the rear of the car to the front and back again. This means that the fuel already has momentum, which reduces recovery time. This movement of the fuel also keeps the pump cooler and reduces vapor lock. "We never race any hot tracks in the heat of summer, do we?" Dead-head regulators can also cause "creep" which means the fuel pressure tends to slowly increase. Return regulators cannot creep. Dead-head regulators can only be adjusted accurately when the fuel is flowing. Therefore, the engine must be running to adjust the pressure accurately at the carb. The same is true for a Nitrous system. Do you want to take that "guess" that the system is set properly the first time to pop the button on your engine? Adjusting the regulator while the nitrous system is on is tricky at best. Return regulators adjusted with or without the engine or nitrous system operating. Turn on the pump and set the pressure! Simple as that... The one thing that can make the return system operate poorly is too much restriction in the return line. To determine the restriction in the return line, turn the pump on (with the engine or Nitrous off) and back the adjustment screw all the way out. Now check the pressure gauge. You should have less than 3 PSI showing on the gauge (the lower the pressure the better). If you have more than 3 PSI you must reduce the restriction in the return line. This in many cases entails free-flow fittings at the least, and in many cases a larger return line. Nitrous systems are very sensitive to fuel pressure fluctuations. It is highly recommended that you run two independent fuel systems when using Nitrous (preferably with return-style regulators). Two small systems with small pumps, fuel lines and regulators are usually cheaper than one large system anyway. If you must use one large system, use two dead-head regulators installed in parallel, not in series. NEVER use two regulators in a system with a return-style regulator! Any fuel system with a return regulator must have only one regulator. Fuel System Designs For Engines With Nitrous: BEST system --- (two independent systems; return regulators preferred)

An OK system --- (one large system with two dead-head regulators in parallel)

POOR system --- (one large system with two regulators in series "not recommended")

|

Of course the fitting at left is what you want. The restriction of the

fittings at right can be hazardous to your race engine and the consistent

ability to Win Races..

Of course the fitting at left is what you want. The restriction of the

fittings at right can be hazardous to your race engine and the consistent

ability to Win Races..